Date:December 07, 2018 Tags:backlash, cleaning, clearance, crimpers, Dura-Therm, Easy Seal, flexible sealing face, heat, kevlar scraper, leakers, pressure, seal quality, sealing jaws, serrations, temperature

When end seal issues such as leakers or splitting occur, an important initial step is to determine where, and how often, the trouble shows up. For problems that occur inconsistently—perhaps leakers on every other package, or splits only on the top or trailing end seals of the package—you need to determine if the bad seals show up randomly or according to a pattern. Do the problems occur on every package? On both ends of the package?

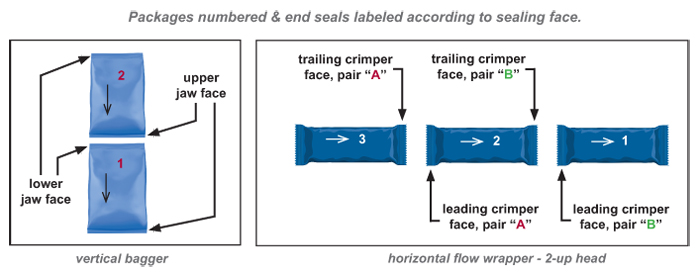

Start out by collecting a series of packages produced by the machine during production conditions. Number the packages sequentially and mark the machine flow direction. If you are working on a horizontal wrapper with multiple crimpers, label each pair (ex: A, B) and mark each seal according to the set of crimpers it came from. Now you can trace the problem seals back to the place they occur.

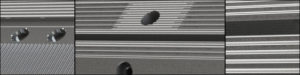

• Clean the crimpers or sealing jaws. Product build-up can cause random, hard to trace problems by preventing the sealing faces from applying adequate pressure and heat.

Learn about custom scrapers and other methods to clean product build-up without damaging serrations.

• Look for backlash on rotary crimper heads. When problem seals can’t be consistently traced back to a particular location on the sealing face or to a specific pair of crimpers, backlash is often the culprit. You should not be able to move the upper shaft independently of the lower shaft. It only takes a little movement to cause a problem, especially if the crimpers have horizontal serrations (parallel to the knife slot).

Get more details on diagnosing and eliminating backlash.

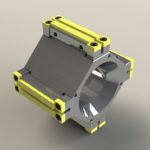

• Assess the condition and set-up of the crimpers or sealing jaws. Use carbon or carbonless paper to make sure the crimpers or jaws are providing even pressure across the sealing face and that the serrations are properly meshed. Problems may be isolated to just one part of the seal or to only one pair of crimpers (where multiple pairs are used).

Discover how carbon or carbonless paper help reveal hidden wear, damage, and set-up issues.

Review clearance and pressure adjustments on horizontal wrappers.

• Check the temperature of all sealing faces along their entire functional length with a pyrometer, making sure that all heaters are functioning properly.

Learn how to achieve more consistent, responsive heat transfer.

• Check the knife set-up. On horizontal wrappers a knife that that is adjusted too far out can, especially at higher speeds, push the crimpers apart as they rotate through such that the pressure applied to the leading seal of the following package is reduced and leakers develop. You can often hear, or put your hands on the machine and feel, when a knife is striking the anvil with excessive force.

Explore methods to optimize knife and anvil set-up.

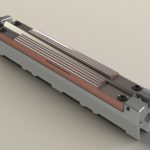

• Upgrade crimper and sealing jaw design. Sometimes inconsistent seal quality results when operating conditions such as line speed, machine condition, and the film in use combine to push the edge of what works and what doesn’t, leaving little room for variations that occur during production. In these cases alternative crimper and sealing jaw designs can create a larger, more forgiving operating window where consistent, quality seals are produced.

Crimpers and Sealing Jaws made from Dura-Therm material provide more consistent, responsive heat transfer without sacrificing durability.

Serration patterns and custom designs such as FRED (Fracture Relief Design) can be matched to your specific product, film, and operating conditions to maximize seal quality and consistency.

Flexible sealing faces for heat seal and cold seal films accommodate extra film layers at the fin seal to help seal off leakers and prevent crushing and splitting without sacrificing durability.

Easy Seal quick-change crimpers for heat seal and cold seal films facilitate more precise set-ups and reduce change-over time from hours to minutes.

Contact Gearpackaging Corporation for help with troubleshooting any type of sealing, cutting, or forming problems that impact your package quality and productivity.

Contact: Tony

Phone: +86-188-1682-5234

Tel: +86-188-1682-5234

Company: Shenzhen Gerong Industrial Corporation Limited

Add: Shangxue Technology Industrial Park,Jihua Road, Bantian, Longgang District, Shenzhen,Guangdong,China