X-Ray Inspection Machine for Food Products: Safe and Sealed

X-ray systems provide a valuable, time-saving method for inspecting packaged food and other products.

Most modern packaging equipment will integrate seamlessly with X-ray systems, providing safe and sealed packages that will uphold your reputation for providing the highest quality products.

Today we're talking with Emmil Gaucher of Peak Equipment to learn more about X-ray inspection systems.

How does X-ray inspection work?

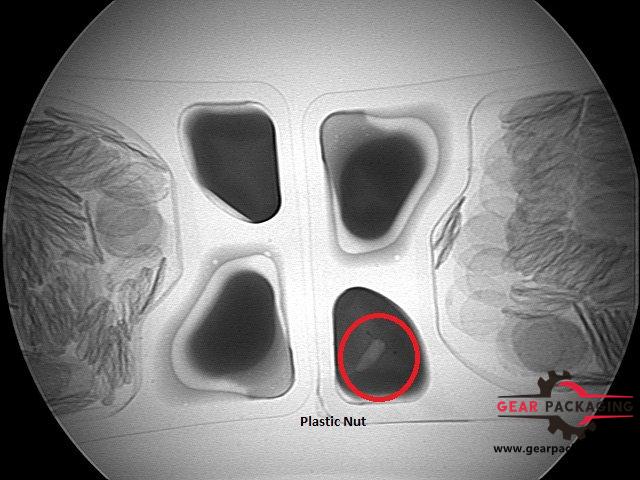

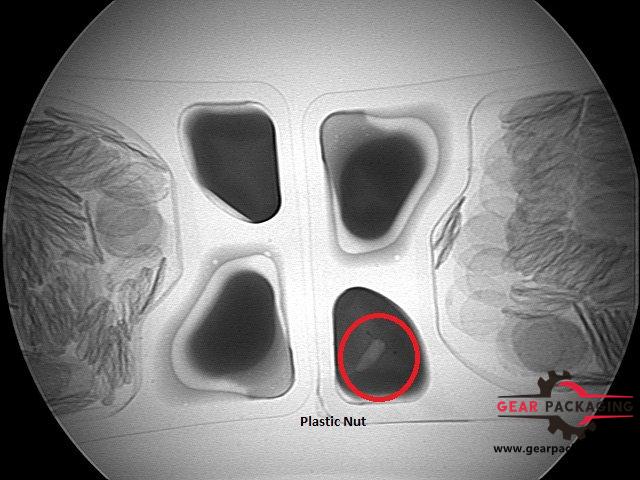

Emmil Gaucher: An X-ray beam is passed through the item to be inspected, and a photodiode array on the other side of the item picks up the radiation that gets through. The photodiodes give out a voltage or current signal depending on the level of X-ray that they detect, which is then converted into a greyscale image that can be easily saved. If inclusions are present which are denser than the product, these will show up as darker patches, where less X-ray radiation was able to get through. Voids and fissures will show up as lighter, as more radiation is able to penetrate. The system can be set to automatically reject items that have either type of defect.

What advantages does X-ray inspection provide in packaging?

EG: X-ray inspection picks up inconsistencies in materials. In a pack, or in a flow of product passing a given point, it can detect pieces of bone, stone and glass and of metals such as iron, steel, stainless steel and aluminium, as well as many plastics, such as Nylon, PVC and Teflon. The minimum size of particle that can be detected varies from one material to another, and also depends on the sensitivity of the system.

Foreign bodies are not the only inconsistencies an X-ray system can spot. Voids and broken or missing product pieces show up clearly, opening up whole areas of quality control. These inspection systems can be used to detect a full range of inconsistencies in products packed in cans or in metallized film.

X-ray inspection can also perform a number of other functions, from estimating piece weight to measuring the fat content of meat.

Why should a packaging operation invest in X-ray technology?

Gearpackaging-Packaging-Technologies-Produce-Safe-and-Sealed-Products.jpgEG: Perhaps the most common reason for purchasing X-ray equipment is to demonstrate that one is practicing due diligence with respect to product safety. When metallized film or foil packaging is involved, having an X-ray system is nowadays reckoned to be best practice. Even where a packing operation can get by without this technology, having it in place confers an advantage. Nobody is more conscious of their reputation than supermarkets and other large retailers. Many of these companies will either prefer suppliers who use X-ray over those who do not, or simply insist that all of their suppliers use it.

Foreign bodies in food products can lead to a variety of outcomes among consumers, ranging from mild disapproval and a slight loss of confidence in the product through painful incidents (such as broken teeth) to severe health hazards. Even minor incidents can lead to complaints, while private or criminal legal action often results from illness or death. Actual financial damages can of course range into the millions. The supplier may lose its contract, or at least find that its reputation in the retailer's eyes is severely damaged.

As mentioned previously, X-ray inspection can pick up imperfections unrelated to contamination. These include:

Voids or gas bubbles

Undersized or missing pieces of product

Underfilled compartments in ready meals

Product with cracks or fissures

Agglomerations (grains stuck together) in powdered products

Metal ties or other securing devices missing or out of place.

The system can also estimate the weights of individual items in a pack if these are sufficiently separated. This enables rejection of packs which have underweight pieces.

How safe are X-ray systems?

EG: As you might expect with a technique that is now so widespread, X-ray inspection has become a very safe part of the packing line. Radiation is contained in the inspection chamber and protected by the geometry of the machine itself and by special curtains, made from the material used to protect radiographers in hospitals. An operator should not be able to receive a significant radiation dose, even by deliberately inserting a hand into the chamber, as machines should be provided with full infeed and outfeed tunnel guard systems to stop this from happening. The radiation dose absorbed by inspected food is also insignificant.

Nevertheless, all due care should be exercised and any regulations on training or monitoring scrupulously observed. You should also ensure that you provide any monitoring of the equipment or its operators that local regulations demand.

Gearpackaing has many years of experience designing fully integrated packaging solutions including X-ray for many industries.