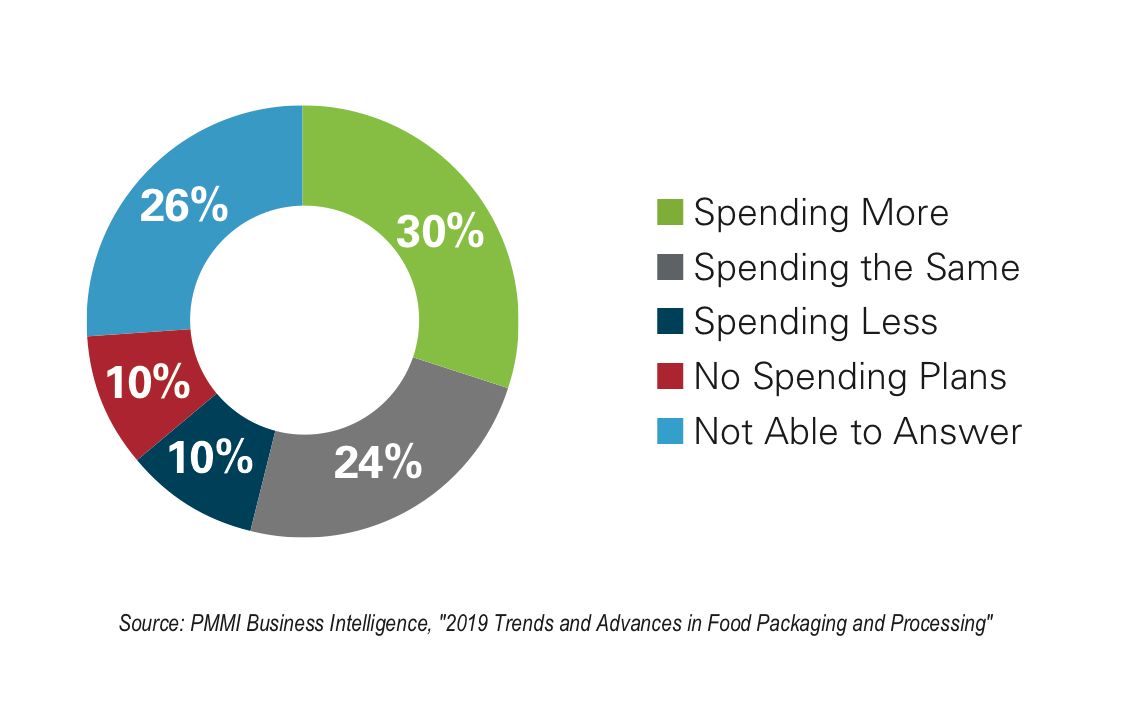

According to the new PMMI Business Intelligence report “2019 Trends and Advances in Food Packaging and Processing,” 54% of food processing operations predict capital spending on processing equipment in the next 12-24 months. Areas of planned spending for processing equipment include:

• Mixers

• Refrigeration

• Oven fryers

• Check weighers

• Metal detection

• ESL (extending shelf life)

• Bowl lines

• Cookers

• Grinders

• Conveyors

• Glaze fillers

• Auger fillers

• Volumetric fillers

• Homogenizers

• Milling

• Slicers

• Whey processing

• Waste processing

• Thermal processing

“We are adding more aseptic equipment to extend shelf life,” said one Production Process and Safety Engineer at a Fruit Processing manufacturer.

All of the food companies interviewed are compliant with FSMA regulations but want suppliers to help them stay compliant. The equipment needs suppliers were asked to consider include: Reliability for consistent quality; visual inspection to identify mis-labeling or foreign objects; traceability, which should be automatic and well documented; worker safety, which is paramount; and, data collection capabilities to validate manufacturing practices.

Improvements to sanitation equipment, in particular, should focus on clean lines with easily removable assemblies. “We need better practices in place for the people that clean equipment; we are looking to the machine supplier for more specific cleaning instructions and procedures,” said one Engineering Manager for shelf stable products.

Improvements food companies are looking for on processing equipment to prevent food contamination include:

• No harbor points, no hollow tubing

• Open frame designs

• Easy to disassemble and reassemble to reduce cleaning times

• Stainless, easy to clean surfaces

• Complies to IP69, IP66, and IP65 standards

• Washdown enclosed components

• Clean in place (CIP)

Other areas of need include tool-less reassembly, integrated CIP and dry cleaning improvements. Some comments from respondents:

“Equipment construction needs to be designed for easy cleaning to prevent contamination due to allergens and should include tool-less disassembly and reassembly of the machine,” said one Director of Engineering at a bakery.

“More CIP systems need to be fully integrated to enable easier food safety management,” said one Engineer Sr. Manager for a breakfast food company.

“The processes of cleaning for dry materials - wiping, blowing, and vacuuming - really need improvement,” said one Packaging Engineering Manager of ingredients and flavors.

Contact: Tony

Phone: +86-188-1682-5234

Tel: +86-188-1682-5234

Company: Shenzhen Gerong Industrial Corporation Limited

Add: Shangxue Technology Industrial Park,Jihua Road, Bantian, Longgang District, Shenzhen,Guangdong,China