Refining and Eliminating Wrinkles and Creases on Vertical Baggers

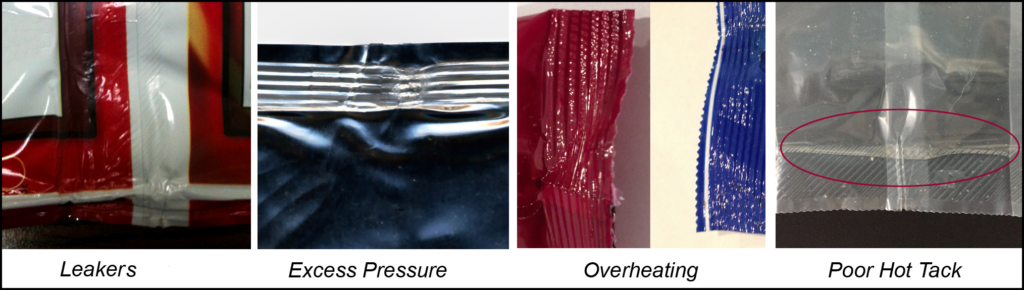

Varying thicknesses of film at the end seal can cause sealing problems, especially at the transition points of multiple film layers created by the fin or lap seal, gussets, wrinkles, creases, and at the corners. Applications of pressure and heat must be great enough to cause the sealant layer to flow into and seal off these voids. However, excess pressure can easily crush or split the end seal, while overheating distorts the seal and can cause poor hot tack, where the film springs back open, or “moons,” before the seal can set.

The operating window for creating quality seals can be elusive, resulting in packages that leak, are distorted, and have little appeal to consumers.

An important step in troubleshooting these issues is to eliminate unintended wrinkles and creases. This post, the second in a four-part series, will examine this process on vertical baggers; Part 1 covered these issues on horizontal flow wrappers.

Any impediment that disturbs the even flow of film can distort packages and create leakers; a combination of factors is often to blame. To find the causes of these problems and fix them we recommend a comprehensive analysis of design, condition, and adjustment, beginning with the film roll and following along sequentially as the film is unwound, formed, filled, and sealed.

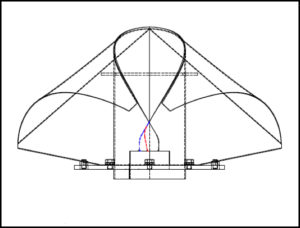

Film Contact with the Forming Collar

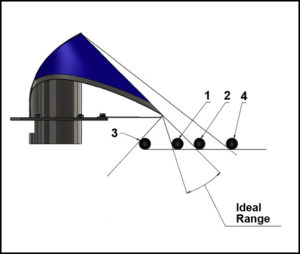

The wing of the forming collar should completely and evenly support the film as the flat web is formed into a tube. Too much, too little, or uneven tension can cause wrinkles and creases.

- Position the rollers so that there is even contact between the film and the forming collar (in the ideal range between options 1 and 2 above).

- Avoid adjusting the rollers so that the film feeds at a downward angle to the forming collar (option 3). This set-up will prematurely wear the edge of the former.

- Make sure the rollers do not lift the film off the surface of the forming collar (option 4).

- Make sure the rollers are positioned parallel to the leading edge of the former wing, so that tension is equal across the film web.

- Improperly aligned film rollers cause undue wear to the lip of the forming collar, which can create or compound problems with wrinkles and creases.

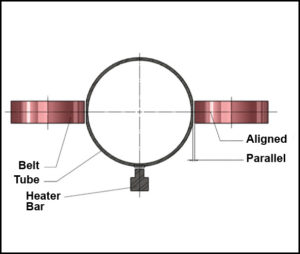

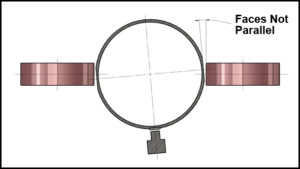

Equal Film Drive

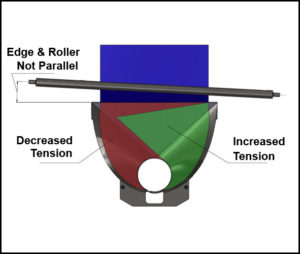

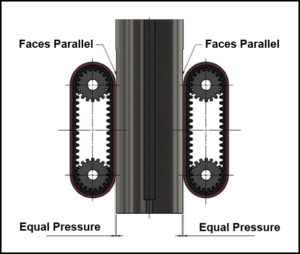

Unequal tension between the drive belts and the film tube can create wrinkles and creases.

- Make sure the drive belts are adjusted and the forming tube is installed so that equal pressure is applied on each side of the film tube.

- Ensure that the forming tube flats are aligned with the drive belts.

- Make sure that the forming tube is not twisted.

Forming Set Condition

Wear and damage of forming sets can easily go unnoticed, and can create problematic wrinkles and creases. Most damage tends to occur when formers are installed and removed from the machine.

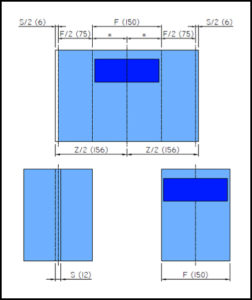

Forming Set Design and Construction

Forming sets must be properly designed and constructed for your specific package specifications in order to produce smooth, appealing packages without unintended wrinkles and creases.

-

Expect properly designed forming sets to be consistently produced from order to order, such that their installation requires minimal need for time-consuming readjustments to film rollers, drive belts, and the back seal.

Customized Solutions

Contact Gearpackaging Corporation about the unique requirements of your packaging application—the product, seal requirements, machine design and condition, film, line speed, and other variables. We will help you create customized solutions for improving package quality and performance such as parts redesign, developing optimal set-up and adjustment procedures, and training.E-mail Address:gearpacking@gmail.com