Description:

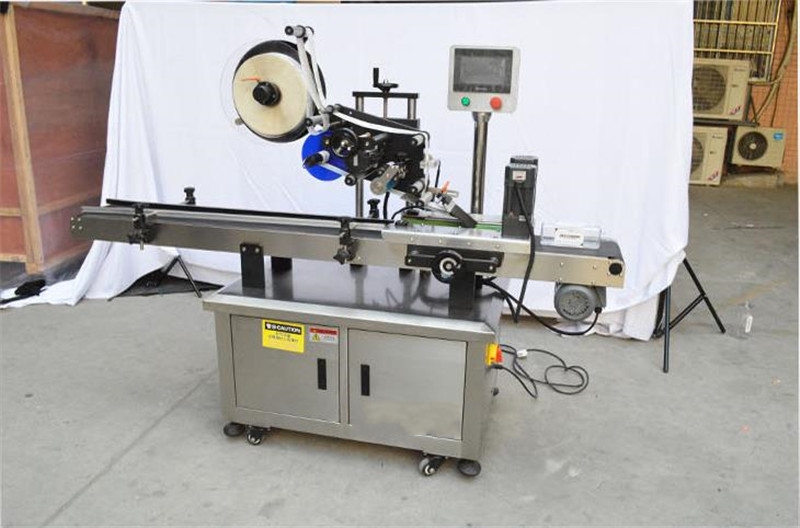

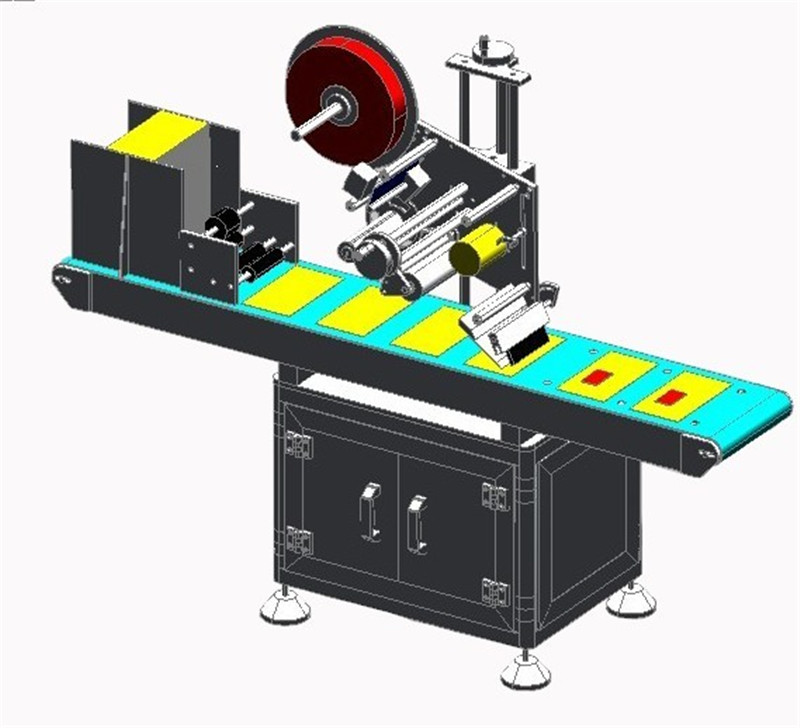

Fully automatic plane flat surface paging labelling machines

This machine is suitable for plastic paper card pouch cards hang tag paper plastic film flat surface products.

The following is the standard model technical parameters, other special requirements and functions, can be tailor-made

No.

The main electrical control components for the installation of

equipment and PLC line.

Human-machine dialogue window.Adjust various parameters

and control the operation of the labeling machine.

Technical Parameters

Applicable scope

Technical Parameters

Applicable scope

Applicable labels

Length:6mm~250mm

Applicable product size

No request(Depending on pipelining parameters)

Width:6mm~130mm

Outside diameter(mm):φ280mm

Inner diameter(mm):φ76mm

Labeling speed

Step forward:40~150pcs/min

Power

Traction step:380W

Servo:50~200pcs/min

Traction servo:830W

Labeling accuracy

±1mm

Weight

About 180kg

Applicable power supply 220V

220V 50HZ

Equipment size

(length×width×height)1100mm×700mm×1450mm

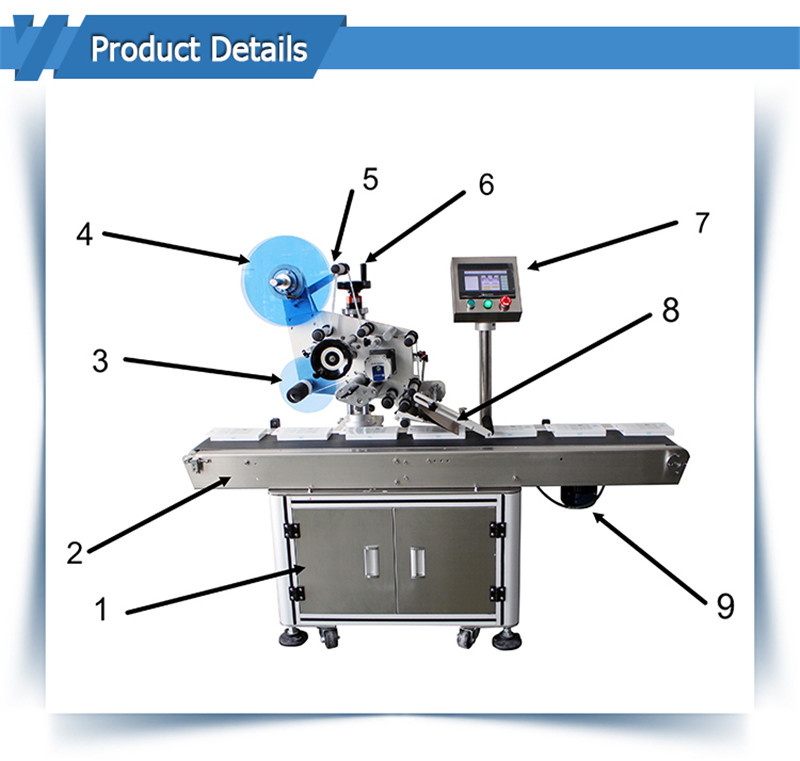

Mechanism Name

Descriptions

1

Control

Electrical Box

2

Conveyor mechanism

For delivery to be labeling products and labeling products.

3

Receiving

mechanism

Used to recycle glassine paper of labels.

4

Tray

Used to put the label roll.

5

Roller

Keep the label tension.

6

Adjusting Mechanism

Used to adjust the machine for each angle

7

Touch Screen

8

Stripping Standard Plate

Peel the label.

9

Transport Motor

Providing traction power for conveyor mechanism

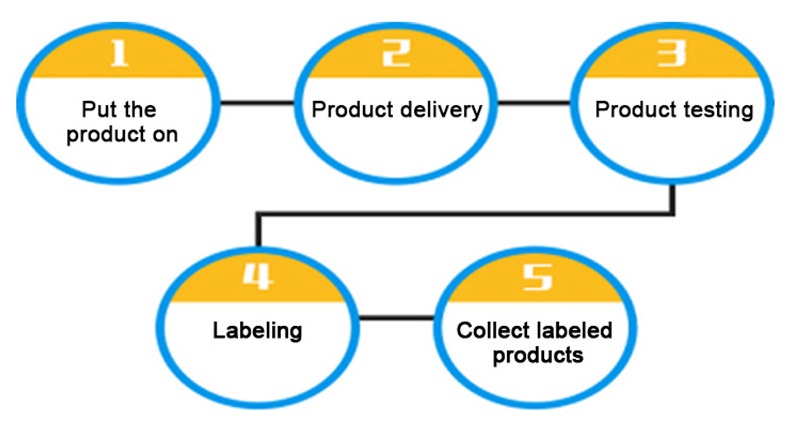

Working flow:

The labeling Machine is suitable for all kinds of objects with plane surface, such as boxes, bottles, cans, etc.

Widely used in cosmetic, drinks, chemical, medical, food industry, stationery CD, various oil, etc,

which can highly improve productivity and product quality. flat labeling machine

Configuration specification:

|

Electrical equipment |

Quty. |

Type |

Electrical equipment |

Quty. |

Type |

|

Label electric eye |

1set |

Leuze/DataSensor |

Tracing motor |

1set |

YAKO/Leadshine |

|

PLC |

1set |

Panasonic |

Motor driver |

1set |

YAKO/Leadshine |

|

EUT electric eye |

1set |

Panasonic |

Touch screen |

1set |

MCGS |

|

Conveyor motor |

1set |

Wanshsin/OPG/JSCC |

Motor speed controller |

1et |

Wanshsin/OPG /JSCC |

|

Labeling speed |

30-200p/min |

||||

|

Labeling accurate |

±1mm |

||||

|

Product scope |

L*W*H:40mm~400mm*40mm~200mm*0.2mm~150mm |

||||

|

Label scope |

Width20-150mm,Length6-150mm |

||||

|

voltage |

220V |

||||

|

Equipment measurement |

L*W*H:1600×780×1400 |

||||

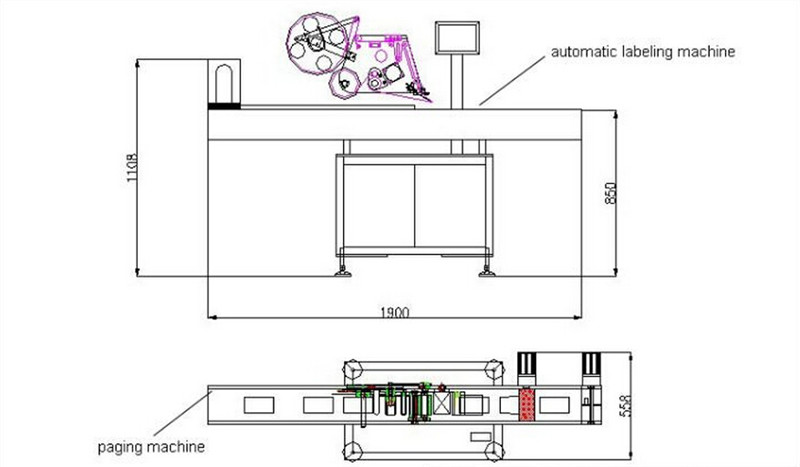

Machine drawing of plastic paper cards laebling paging machine automatic

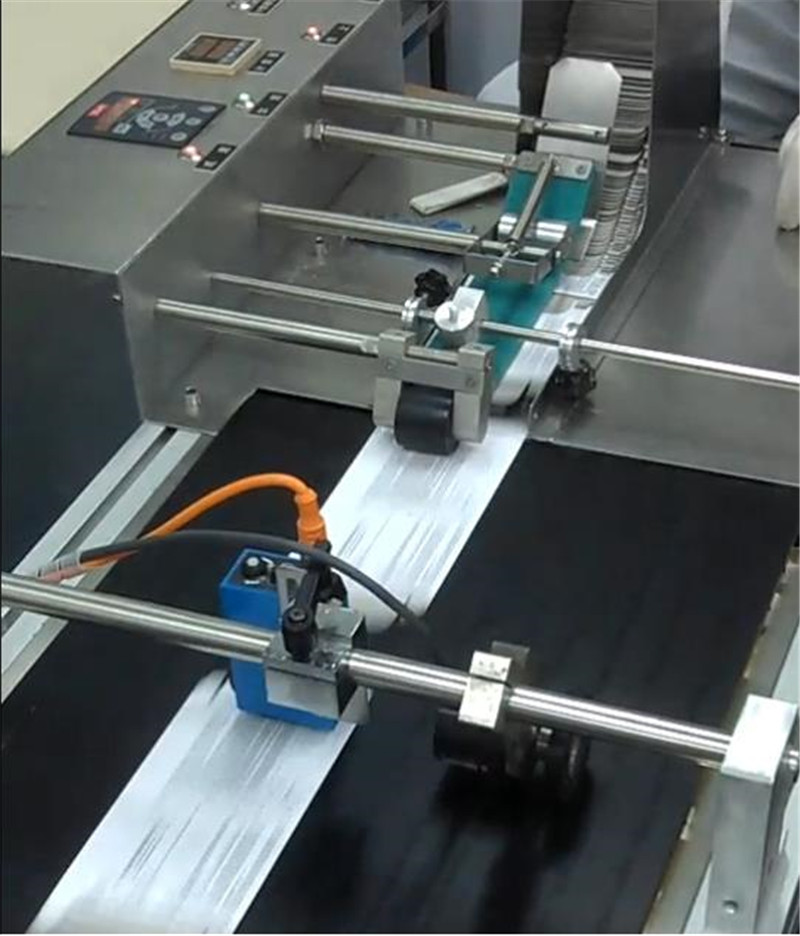

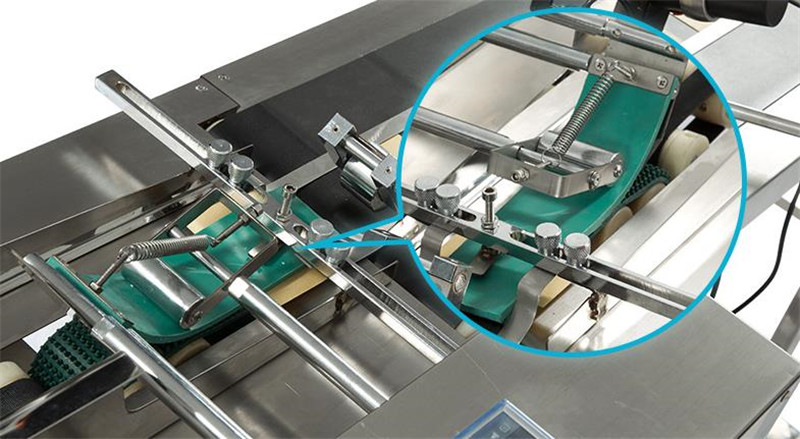

Paging machine,cards sperate mechanism:

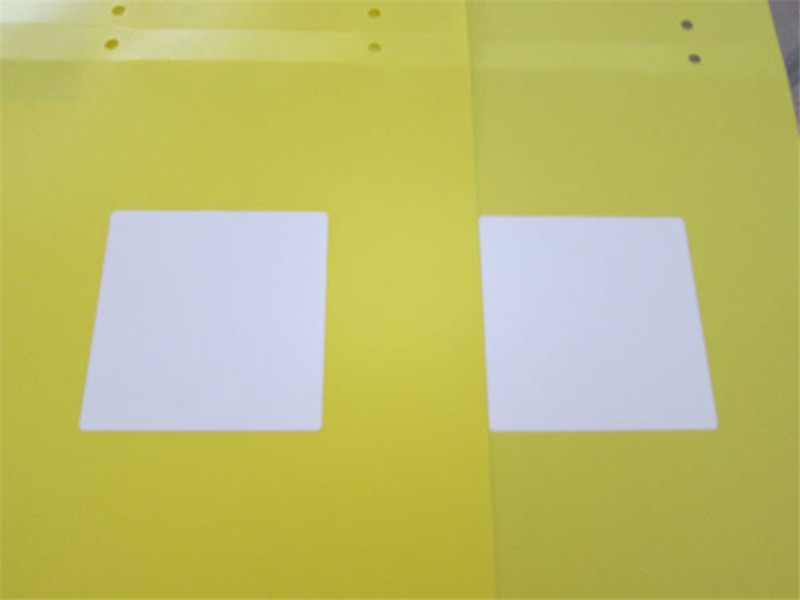

Application scope,sample product picture by flat automatic labeling machine,customers' samples:

Custmized builded machine for different flat products according to customers' requirements:

Packaging&Shipping

How to Buy our label machine:

The process is as follows: (we Accept T/T,Western Union etc)

1. Tell us the Items details and quantity you order. we make a PI for you.

Then You pay the down payment 50% of the total amount to our company account .

2.After we receive the down payment, we will produce the goods for you.

3.Once we finish the products , we will send you the photos to check and confirm,

4.If everything is ok, you pay the balance amount

5.After we receive the balance amount, we will arrange shipping for you.

Guarantee: for all the machine, it claims three years for guarantee.

(Excluded from the warranty are problems due to accidents, misuse ,

misapplication, storage damage, negligence,

or modification to the Equipment or its components.

ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,

if you need,our technician will go to your place to install and

test the machine and also training your worker to operating the machine

(The time of train depend on you worker).

The expenses (air ticket ,food , hotel,the travelling fee on your country)

should be on your account and you need

paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,

our technician will go to your place to fixed the machine

as soon as possible. The cost should be in your account.(as above).

Contact: Tony

Phone: +86-188-1682-5234

Tel: +86-188-1682-5234

Company: Shenzhen Gerong Industrial Corporation Limited

Add: Shangxue Technology Industrial Park,Jihua Road, Bantian, Longgang District, Shenzhen,Guangdong,China