Description:

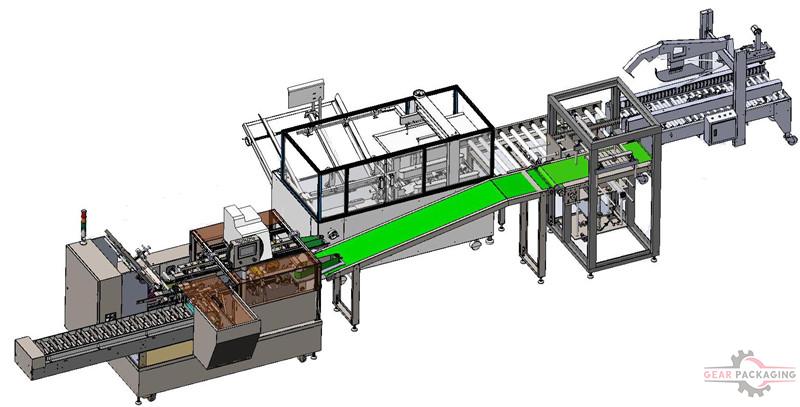

Automatic stick sachet cartoning machine multi lanes box packaging End packaging line

Main parameters of the equipment

Equipment Name: Automatic Cartoning Machine (Adhesive Box)

1. Device function: The product is automatically loaded into the carton according to the specified arrangement. The single machine realizes all functions of opening the box, packing the box, sticking the box and sealing the box at the same time.

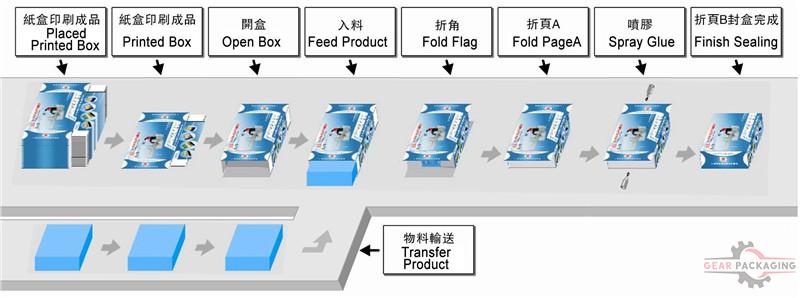

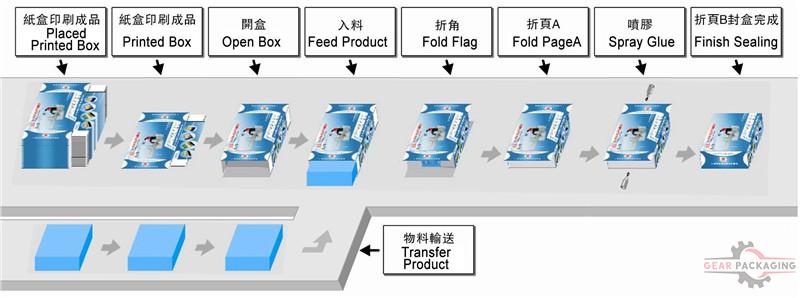

2. Flow chart:

Carton open box bottom molding → Product automatic cartoning machine → Carton sealing → Finish output

Third, technical parameters:

Model customization

Carton size (length * width * height) Customized machine according to customer's sample

Paper requirements range 270 g / m2 ≤ most suitable for paper: 350 g / m2 ≤ 450 g / square meter

Other requirements for the carton The carton indentation is not less than 0.4mm, and there is a pre-folding effect. The ear pages and short pages need to be chamfered.

Production capacity (box / hour) about 10 boxes / minute (25 boxes in a box)

With host power (kW) 1KW

Machine power 3KW

Machine weight (T) about 1200KG

Machine dimensions about L1150*W9300*H1700mm

Fourth, the relevant parts work instructions

1, the box frame mechanism

The cassette holder is used for stacking the position of the paper tray, and 200 to 300 paper trays can be placed at one time. When the paper tray is used up, the paper tray needs to be manually added, and the paper tray holder can be adjusted according to the size of the paper tray. Box holder adds spiral adjustment

If the mechanism is not adjusted (including the carton guide rails, suction cups) and the carton indentation is not deep, it will not open the box.

(The carton indentation is generally above 0.4MM depth, and the carton needs to have a pre-folding effect)

2, material conveyor belt

The material conveyor belt is used to place the product. The conveyor belt can be adjusted according to the size of the product: the two screws can be loosened to move and the material can be adjusted.

Push the baffles on both sides of the grid to prevent the product from being released

3. Feeding port mechanism

Self-test protection system:

1) When sensing the product on the conveyor belt, the machine will automatically suck the box and push the material, otherwise it will not suck the box;

2) If there is product delivery, but there is no paper box on the box, the machine will automatically stop and play a self-detection function.

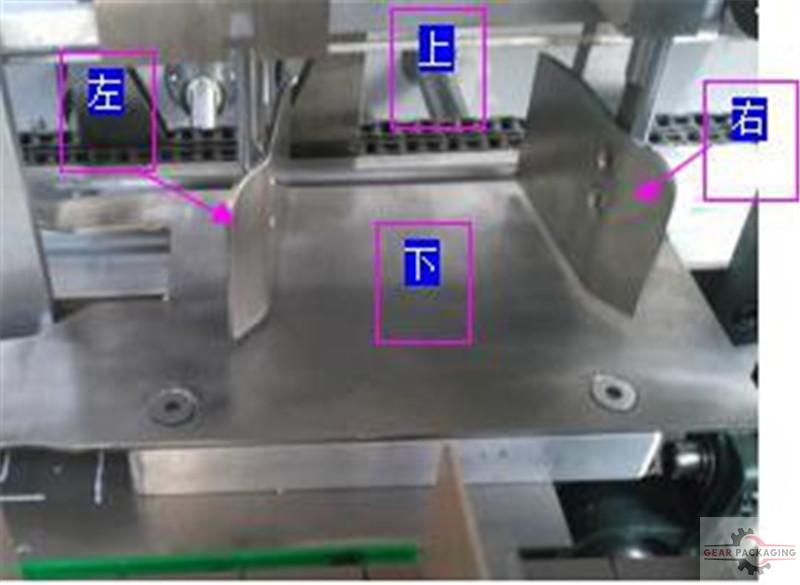

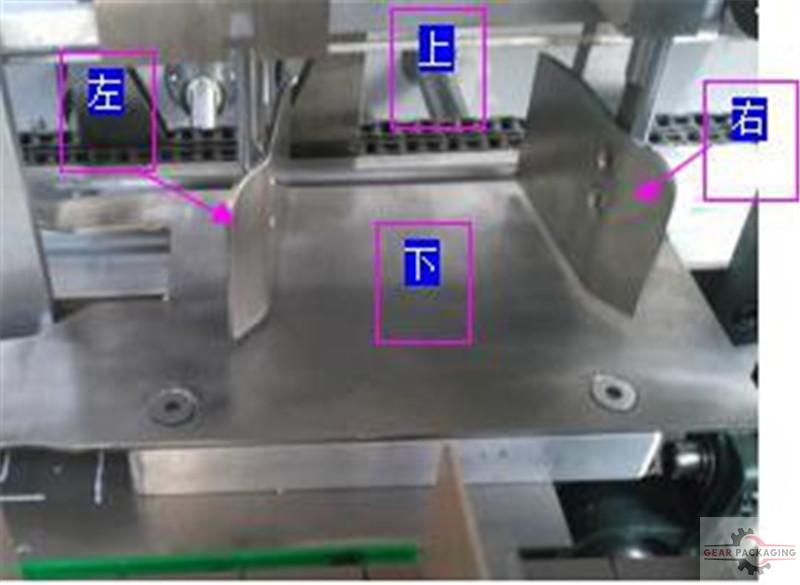

3) When the carton is sent to the pusher opening, there will be four upper baffles (up, down, left, and right) to open the box, so that the product can be pushed into the carton smoothly. If the product does not push in, the machine It will automatically stop and protect the machine and products.

The product and the outer box (length / width / height) need to have a gap of 2-3mm, in case the outer box is too small when pushing the material, can not push in and knock the carton.

4, sealing mechanism (adhesive type)

When the product is loaded into the carton, the machine automatically folds the ears and folds on both sides (as shown).

This position is the specific part that adjusts the length/width/height of the machine. If you need to change the box of another size, this position needs to be adjusted accurately.

This mechanism is equipped with a protective glass cover to prevent sudden impact of other substances and affect the stability of the machine.

Five, the machine machinery configuration part of the description

1) Power supply: single-phase AC 220V/50HZ.

2) The main motors are all made by Taiwan Taichuang products.

3) PLC adopts Siemens (Germany) products, with analog and digital modules and supports communication functions.

4) Main material: The main machine adopts 5 PCT channel steel, and the contact part with the product and the outer casing are made of 304 stainless steel.

5) Electrical components use modular plug-in components, low-voltage electrical appliances (contact ports, air switches, circuit breakers, indicator lights, buttons, knobs, emergency stops, manual control button boxes, power main switches, air switch auxiliary contacts, fuses, etc.) ) Adopt Omron products.

6) Pneumatic valves and cylinders are manufactured by Adak.

7) Solenoid valves use Yadak products.

8) The touch screen is made by Siemens (Germany).

9) Other electrical accessories not mentioned are imported or joint venture brands.

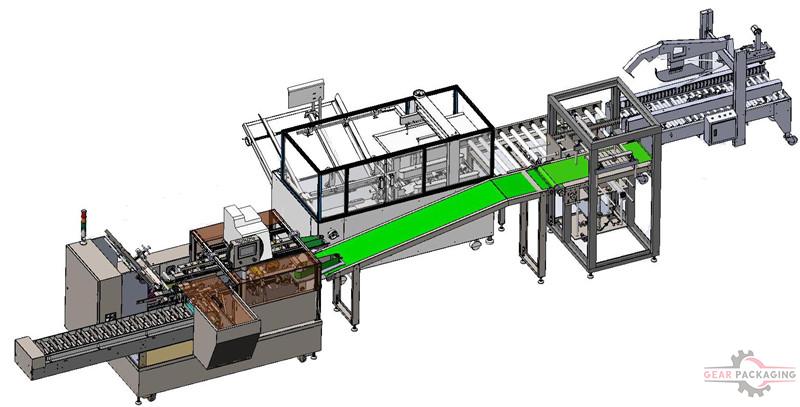

Sixth, equipment name: automatic unpacking and packing and sealing production line (required equipment: unpacking and sealing machine, palletizing and packing machine, finished conveyor belt, folding and sealing machine)

1. Unpacking and sealing machine

Uses: Automatically complete the unpacking, forming, and lower bottom blade folding adhesive tape.

Main features: The box-opening machine is controlled by PLC man-machine interface display, which is convenient and quick to operate; it is the assembly line for automatic unpacking of large-volume carton, automatic folding of the lower cover, and automatic sealing of the bottom tape of the carton.

The main parameters:

Applicable carton : (L)300-480 (W)200-380 (H)200-380MM

Unpacking speed: 0-7 cases / minute

Power / Power: single phase, 220V, 50Hz, 180w

Use air source: 5-6kg/cm2

Use tape (mm): 48, 60, 72

Table height (mm): 650

Mechanical size (mm): L2500xW2000xH1400MM

Mechanical weight (Kg): 250

2, palletizing machine

Uses: The carton is transported from the cartoner to the palletizing machine.

Palletizing method: 10 boxes * 2 rows * 2 layers

Packing speed: 0-3 boxes / minute

Power / Power: single phase, 220V, 50Hz, 180w

Use air source: 5-6kg/cm2

3, folding cover sealing machine

Uses: Automatically complete folding and sealing operations in the process.

main feature:

1. The front cover of the carton is bent by the boat-shaped plate, and the other three blades are pneumatically folded, smooth and smooth, and the sealing operation is completed in one go, beautiful and labor-saving, and can be used with the automatic packaging machinery series.

2, the introduction of a new type of tape dispenser, without the blower blowing the tape, using the tableting device, so that the tape is standing upright without bending and can not be pasted.

3, left and right belt drive (3240 * 80 plus guide bar), the main drive mechanism uses a special Palin seat high precision, low noise, increase the belt life.

4. The trapezoidal screw is used to adjust the width, width and height synchronously, and the structure design is reliable.

5. The length of the sealing tape at both ends of the carton is 60~65mm, which can be customized 80mm, 100mm.

6, the standard specifications of the sealing machine, parts are available at any time.

The main parameters:

Machine size (mm): L 1700 * W 950 * H 1300

Applicable carton (mm): (L) 150 ~ 500 (W) 150 ~ 500 (H) 150 ~ 500

Table height (mm): 470 ~ 780

Sealing speed: 18 m / min

Use power / power: 220V 50HZ / 90W*2

Use air source (kg/cm2): 5~6

Tape width (mm): 48, 60

Mechanical weight (Kg): 150